PRODUCTSGAS Systems

At Agroel, we believe that our innovation and constantly improved products, together with the approach assuming the care of each implementation of the controlled atmosphere technology, will translate into your measurable success.

Our commitment is reflected in maintaining the excellent quality of our customers’ collections throughout the entire storage period.

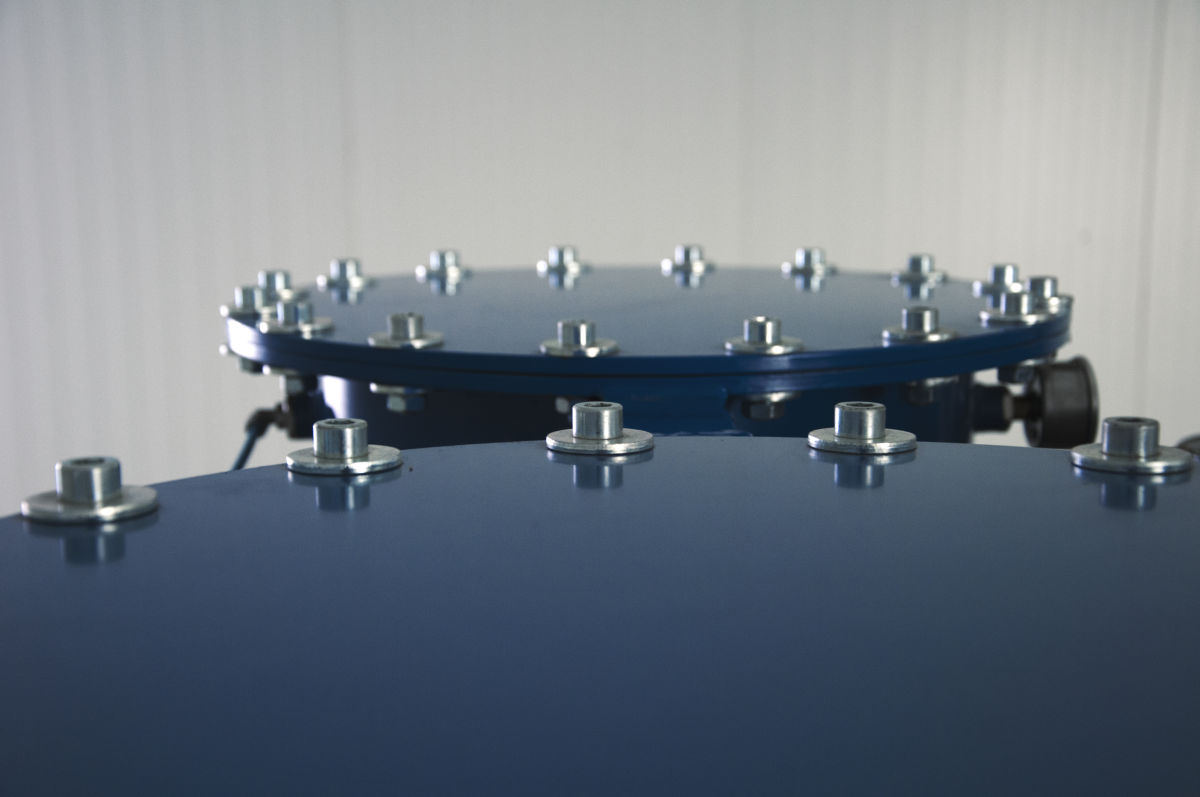

In our company, we design, manufacture and implement comprehensive installations of a controlled atmosphere for the storage of fruit and vegetables. Our devices are energy-saving, durable, made with attention to the smallest details, which makes them probably the best that can be purchased on the European market.

The solutions we implement are designed to make your work as easy as possible.

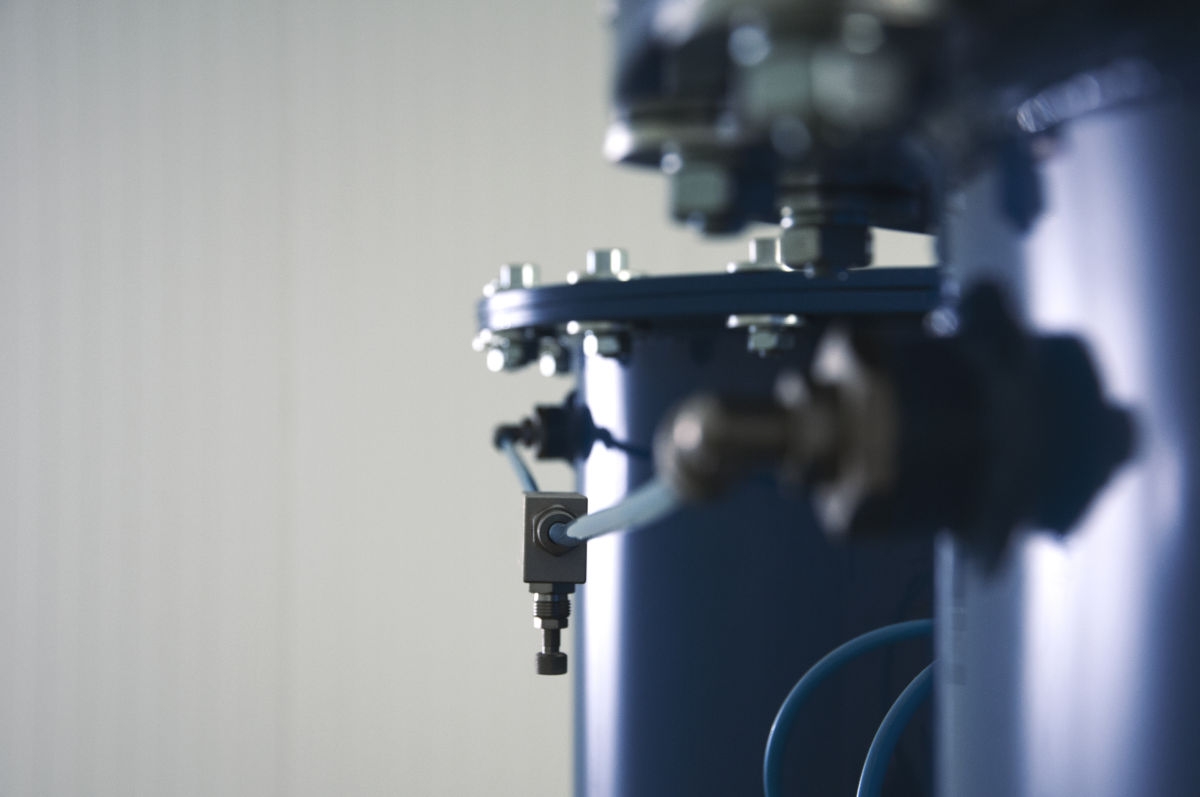

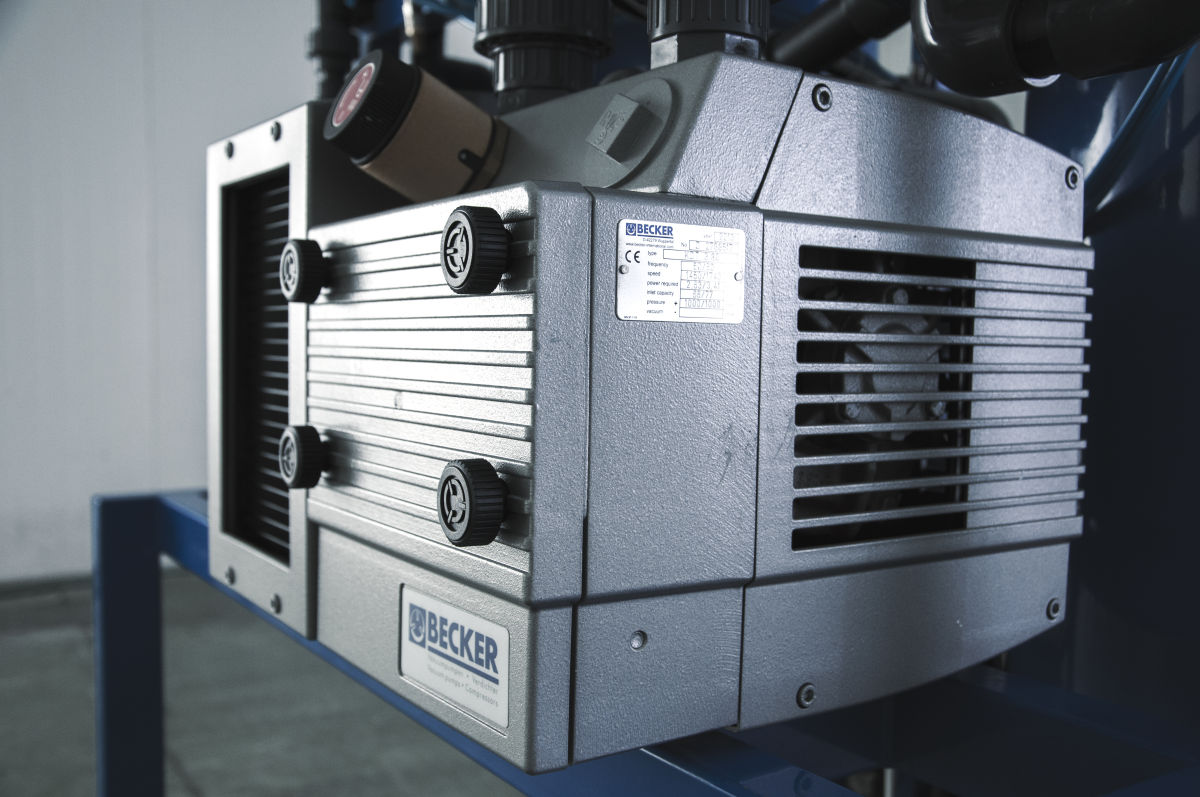

Our devices are characterized by a high level of technological advancement, which is reflected, among others, in the developed possibilities of communicating with the user. The GSP CO2 scrubbers (coal scrubbers) produced by us use GSM technology and can be connected to the network using Wifi and Ethernet. They send SMS and email messages and communicate with an external server, improving the remote service capabilities. Specially selected activated carbon based on coconut shells ensures many years of work with the highest efficiency. The design solutions used, incl. the disc air distribution system allows you to work with ultra-low oxygen concentrations, thanks to the precise removal of oxygen from the bed after the regeneration phase.

The GSG nitrogen generators we offer work in energy-saving VPSA technology. We use oil-free compressors in them, which allow us to extend the life of the molecular sieve bed by up to 100% compared to the high-pressure technology (PSA). Our devices have been designed to facilitate their transport as much as possible. The height of the basic models is only 165 cm!