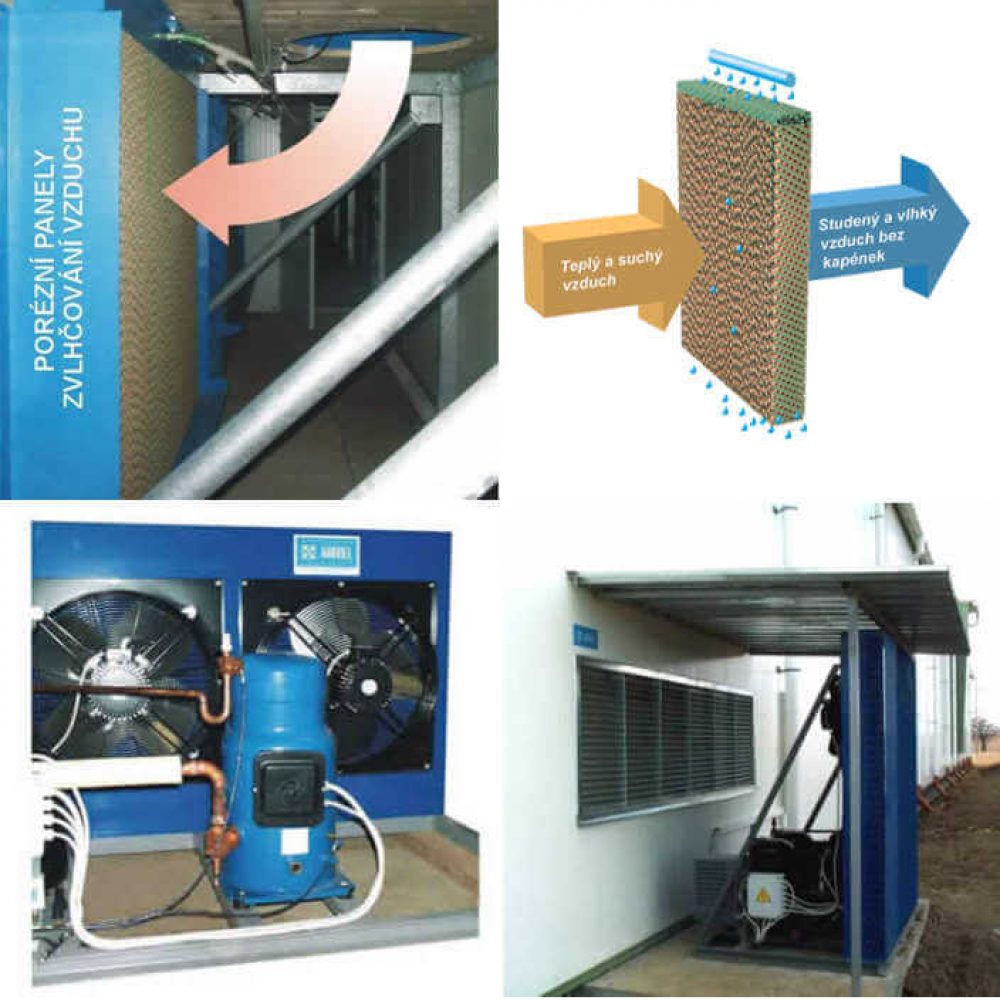

The use of humidifying pads provides more benefits, as well. Water evaporation also results in cooling the air that passes through the pads. This simple physical principle leads to further substantial savings for storage keepers. Air cooled this way can be used to cool produce and preserve its water content! Agroel has introduced the humidifying pads in a wide range of air-treatment systems. The cooling effect feature is also useful in ventilated storage areas. During suitable weather conditions even outside air that is warmer then the produce can be used for cooling. Its temperature can be decreased by several degrees and humidified at the same time. This way of cooling is significantly more economical than cooling with refrigeration systems. Agroel now supplies systems that are equipped with all three cooling methods: ventilation, refrigeration and humidification, and our system is one of the most advanced on the market.

In general, produce that requires high levels of humidity benefits from our system, especially in the reduction of softening and the loss of weight. These concerns mainly impact potatoes, root vegetables and apples, whose specific biological storing stages must be guaranteed. Agroel control systems are equipped with many product-specific modes and contribute to successful storage.

Refrigeration must be used if a constant produce temperature cannot be guaranteed by ambient ventilation alone. In such cases, a refrigeration system functions as a backup to a ventilation system and provides an alternative source of cool air in case it is not available outside. A mass of cooled stored material has a large temperature capacity, and it can maintain its temperature for a certain time even in those periods of warmer weather. Not every storage facility must be equipped with refrigeration. We recommend considering these issues in making a decision about installing a refrigeration system:

- Storing temperatures and storing seasons – availability of cool outside air changes during the year

- Geographical location of the storage facility

- Storage economy – refrigeration is not affordable for some products, while for others it is crucial to maintain top quality

- Sensitivity of the stored product to temperature changes

- Frequency of loading and unloading

Stored products form organic substances (e.g., ethylene and CO2) that negatively affect the quality of the produce or speed up unwanted ripening. Agroel therefore recommends a combination of ventilation and refrigeration systems so periodic exchanges of storage air can be performed and concentration of gasses reduced.

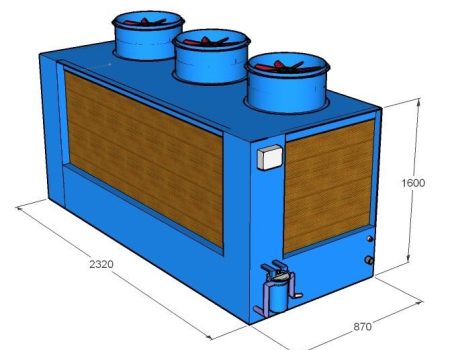

Agroel refrigeration systems are designed with respect to the arduous conditions under which they are often operated. Refrigeration can be installed in the pallet storage units (ISK models CP) as well as in bulk storage areas.

Main specifications of our refrigeration systems:

- Installed compressors are hermetic types, made by renowned producers like Maneurop or Copeland

- The „Scroll“ compressor technology guarantees smooth operation in difficult conditions

- Robust evaporators with large surface areas provide long lifespan and high efficiency

- Fast service throughout Europe in cooperation with partner companies